Zhenjiang Moeller Selected as the Ministry of Industry and Information Technology's 2023 Intelligent Manufacturing Outstanding Scene

Release Time:2024-01-02Source:Clicks:2826Author:

Recently, the Ministry of Industry and Information Technology (MIIT), National Development and Reform Commission (NDRC), Ministry of Finance (MOF), State-owned Assets Supervision and Administration Commission of the State Council (SASAC), State Administration for Market Regulation (SAMR) jointly announced the 2023 Intelligent Manufacturing Demonstration Factories (IMDF) and the list of excellent scenes. Zhenjiang Klockner-Moeller Electrical Systems Co., Ltd.'s "Digital Upgrading of Key Component Assembly of LV Distribution Cabinet - Human-Machine Collaborative Manufacturing Intelligent Scenario" has been successfully selected as one of the 2023 Outstanding Intelligent Manufacturing Scenarios of the Ministry of Industry and Information Technology (MIIT).

In recent years, Zhenjiang Klockner-Moeller Electrical Systems Co., Ltd. has been focusing on the goal of high-quality development, taking "digitization and intelligence" as the gripping hand, vigorously pushing forward the upgrading of "Intelligent Manufacturing" capability, gradually constructing discrete intelligent manufacturing environments based on the Intelligent Factory of Power Transmission, Distribution and Control Equipments, and speeding up the pace towards the Intelligent Factory, and has been successively awarded the Model Intelligent Workshop in Jiangsu Province, Intelligent Manufacturing Demonstration Factory in Jiangsu Province, and the national-level specialized and innovative "Little Giant" enterprise.

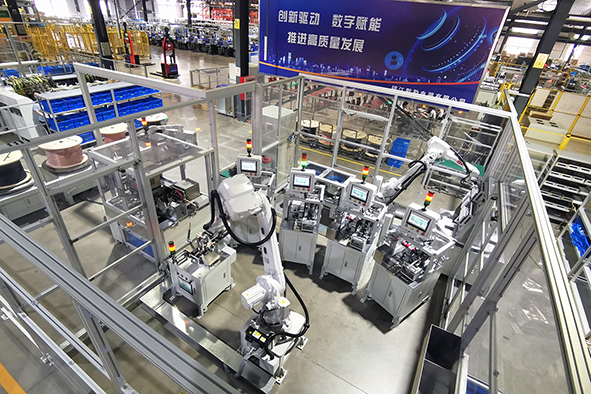

With the continuous growth of user demand, Zhenjiang Moeller seeks for new changes in the "intelligent manufacturing" link, combining the characteristics of product customization and diversified demand, and developed and upgraded a number of digital production lines and intelligent equipments for the key components and key processes of LV distribution cabinets, including distribution cabinet drawer unit production line, frame robot assembly line, fully automatic cable processing line, intelligent copper bar processing center, etc., which achieved full coverage of key manufacturing processes for the product; Through the application of industrial Internet of Things, big data mining and intelligent algorithms, human-machine collaboration and other technologies, intelligent equipment and information systems are efficiently integrated, effectively promoting enterprises to achieve operational goals of improving manufacturing efficiency, enhancing product quality, reducing energy consumption, and improving resource utilization, laying a solid foundation for enterprises to enhance their comprehensive competitive strength.

In the future, Zhenjiang Klockner-Moeller Electrical Systems Co., Ltd. will continue to promote the integration and upgrading of digital design, digital manufacturing, digital management, to create "smart manufacturing" hard power with innovation, empowering enterprises to go deeper and farther on the road of high-quality development, and playing a leading role in the transformation and upgrading of the LV complete electrical industry.

Note: In order to implement the "14th Five-Year" Intelligent Manufacturing Development Plan, the Ministry of Industry and Information Technology (MIIT), National Development and Reform Commission (NDRC), Ministry of Finance (MOF), State-owned Assets Supervision and Administration Commission of the State Council (SASAC), State Administration for Market Regulation (SAMR) jointly carry out the 2023 Intelligent Manufacturing Pilot Demonstration Actions, aims to select a number of intelligent manufacturing excellent scenarios, build a number of intelligent manufacturing demonstration factories and intelligent supply chain, and select a number of pioneer enterprises in various industries and fields, so as to push forward the high-quality development of intelligent manufacturing.